Capabilities

Compart Systems offers a wide range of industry-focused capabilities to our customers. These capabilities are seamlessly integrated to ensure that we deliver products and solutions that meet or exceed our customers’ expectations and requirements. Below is a summary of our capabilities and the services we provide:

- Engineering Expertise: Advanced engineering solutions tailored to specific industry needs.

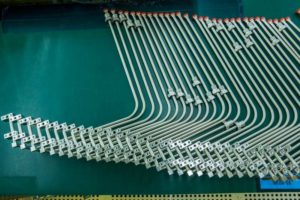

- Precision Manufacturing: High-precision CNC machining and complex manufacturing processes.

- Quality Assurance: Rigorous quality control measures to ensure product reliability and performance.

- Integration Solutions: Comprehensive integration of systems and technologies for optimal functionality.

- Customer Support: Dedicated support services to assist customers throughout the product lifecycle.

This structured approach ensures that we consistently deliver high-quality, reliable, and innovative solutions to our customers across various industries.

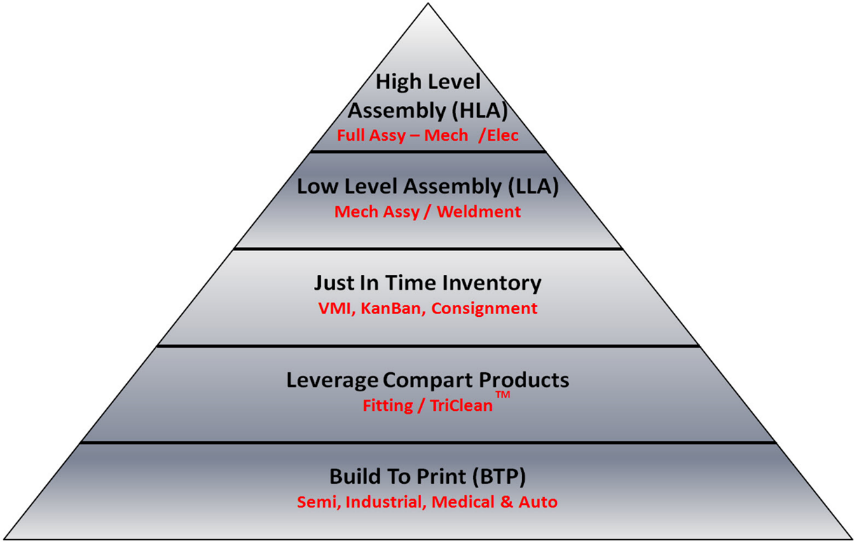

Here’s an overview of the pyramid of capabilities and services that Compart Systems offers to our customers:

With the Semiconductor industry moving to sub 10nm geometries and new leading-edge materials and Semiconductor processes like 3D Nand and Atomic Layer Deposition (ALD), product cleanliness and corrosion resistivity has become the new challenge in flow control products and systems. In 2012 till 2014 Compart Systems working closely with our European Mill supplier, developed a better more homogenous corrosion resistant SEMI F20 UHP raw material for the Semiconductor industry. The investment made by both of us encompassed hundreds of man hours and came at a cost well over $1,000,000 dollars. This commitment and drive to develop this material was a great success and TriClean was developed. TriClean is a Triple Remelt SEMI F20 UHP raw material whose corrosion resistivity properties are greater than 2.5 to 11 times the industry standard SEMI F20 UHP material while lowering if not eliminating unwanted inclusions.

With the Semiconductor industry moving to sub 10nm geometries and new leading-edge materials and Semiconductor processes like 3D Nand and Atomic Layer Deposition (ALD), product cleanliness and corrosion resistivity has become the new challenge in flow control products and systems. In 2012 till 2014 Compart Systems working closely with our European Mill supplier, developed a better more homogenous corrosion resistant SEMI F20 UHP raw material for the Semiconductor industry. The investment made by both of us encompassed hundreds of man hours and came at a cost well over $1,000,000 dollars. This commitment and drive to develop this material was a great success and TriClean was developed. TriClean is a Triple Remelt SEMI F20 UHP raw material whose corrosion resistivity properties are greater than 2.5 to 11 times the industry standard SEMI F20 UHP material while lowering if not eliminating unwanted inclusions.